Industrial accidents

The growing use and application of chemicals means that industrial accidents will continue to happen, and may be exacerbated by risk drivers, such as climate change, urban expansion, and aging of industrial infrastructure.

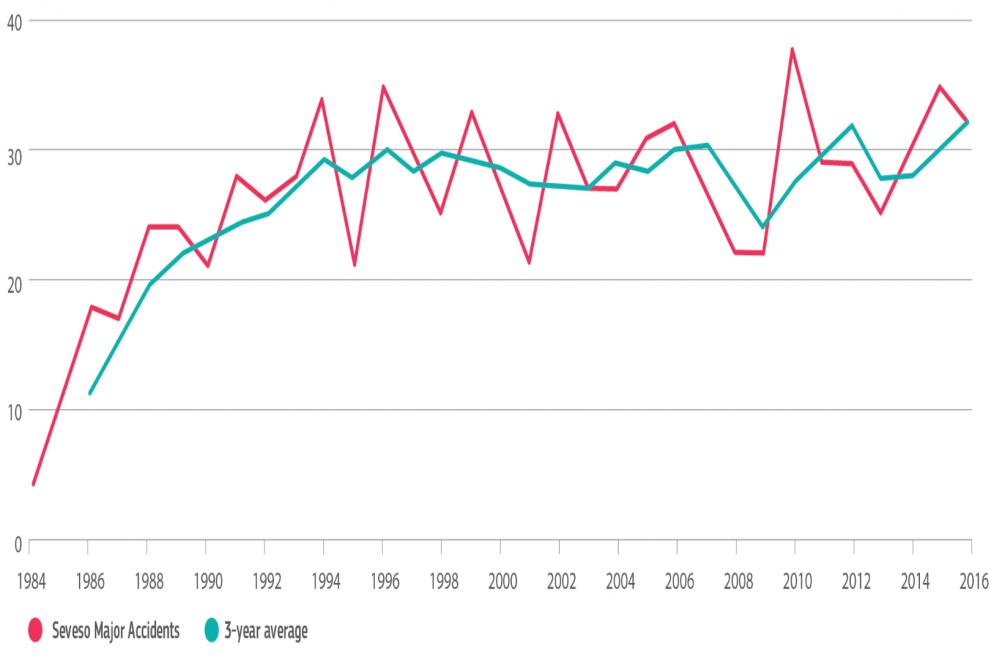

According to data from the online Major Accident Reporting System (eMars), on average, over 30 industrial accidents take place each year. This data does not include accidents in hazardous facilities which are not covered by the EU Seveso Directive or incidents involving pipelines or transport.

The growing use and application of chemicals means that industrial accidents will continue to happen, and may be exacerbated by factors including:

Aging of infrastructure and equipment, associated with poor maintenance levels and inadequate procedures update and associated transfer of know-how can be the source of accident and also serious accident. According to the Organisation for Economic Co-operation and Development’s (OECD) Guidance on Change of Ownership in Hazardous Facilities, a change in ownership of hazardous facilities can increase this risk; if the process is not well managed, the condition and operation of the facility can deteriorate quickly, mainly due to a lack of know-how (procedures) transfer.

More frequent extreme weather events, such as floods, droughts, heatwaves and wildfires, could damage or weaken infrastructure, triggering the release of dangerous substances, explosions and industrial fires, or aggravating the effects of such accidents. Wildfires, for example, can affect industrial facilities via thermal radiation (heat), ember flight, or direct flame impingement affecting vulnerable equipment. The transformation of the areas surrounding industrial facilities also raises concerns about future industrial plant safety in wildfire risk zones; to date, there is no integrated European fire management system to prevent natech accidents triggered by wildfires. Recent research highlights the importance of land-use planning along wildland-urban and wildland-industrial interfaces in order to protect critical infrastructure and industry assets from the impacts of wildfire in a changing climate, in light of their specific vulnerability and potential to trigger cascading effects when damaged.

While development can help strengthen the safety and security of industrial sites, it can also create new vulnerabilities. Process automation, for example, helps to reduce ‘human error’, but also creates challenges related to programming errors and software glitches. Technological changes in response to climate change, such as switching to alternative fuels (including hydrogen and lithium batteries), may introduce new risks (e.g. explosion at hydrogen filling stations for fuel cell cars). Knowledge of public health and environmental risks related to the use of new substances (bio-based chemicals, liquefied natural gas, compressed natural gas, nitrogen and nanoparticles) is still relatively limited.

Insufficient safety/risk management measures, human error, and deliberate malicious acts, including cyberattacks.

Largely based on national disaster risk assessments for EU Member and Civil Protection Mechanism Participating States, the ‘Overview of natural and man-made disaster risks the European Union may face’ aims to foster better understanding of disaster risks facing Europe.

Industrial accidents are considered to be a major risk in Europe, with 27 countries including it in their national disaster risk assessments. There has been little change in assessed risk levels from industrial accidents compared to the 2015 assessments.

Overall, the likelihood and impact of an industrial accident are assessed to be at a similar level across EU Member States: the likelihood is estimated as being low, while the estimated impact ranges from medium to high. Some Member States underline the territorial nature of risk from industrial accidents by assessing it as moderate at national level, but high at regional/local level where industrial establishments are located.

The impacts of industrial accidents may include:

The impact of an industrial accidents is even higher if the industrial site is located in the proximity of an urban areas.

In the EU, major chemical accident risks are regulated by the provisions of the Seveso III Directive, which requires stringent safety measures to be implemented to prevent major accidents from occurring and, in cases where they have not been prevented, to effectively mitigate their consequences for human health and the environment. The Seveso Directive also encourages reporting of near misses and accidents, which is useful for learning purposes. The 2021 Report on the implementation and efficient functioning of the Seveso III Directive showed that between 2015 and 2018, the number of major industrial accidents in EU has stabilised at a low level: 25 per year for 12 000 establishments.

The European Critical Infrastructure Protection Directive generated political momentum and spurred national action on the protection of critical infrastructure against multiple hazards and threats, and several other EU legal instruments indirectly address natech risks, including the Offshore Safety Directive, the Water Framework Directive and the Floods Directive.

Since 1998, the EU has been a party to the United Nations Economic Commission for Europe (UNECE) Convention on the Transboundary Effects of Industrial Accidents, which addresses industrial accidents that have transboundary effects. Similarly, an EU-wide approach to nuclear safety and security has helped ensure that nuclear energy operations in all Member States are carried out and enforced to the highest standards.

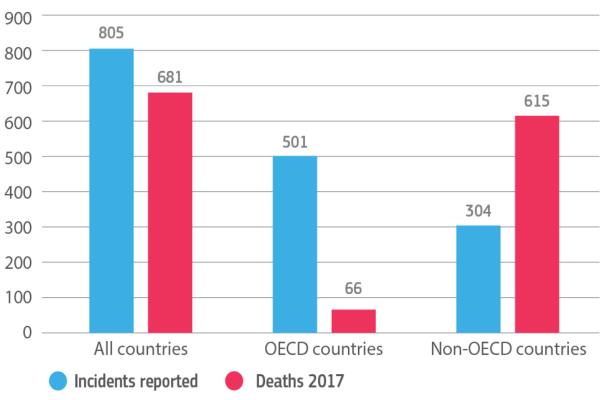

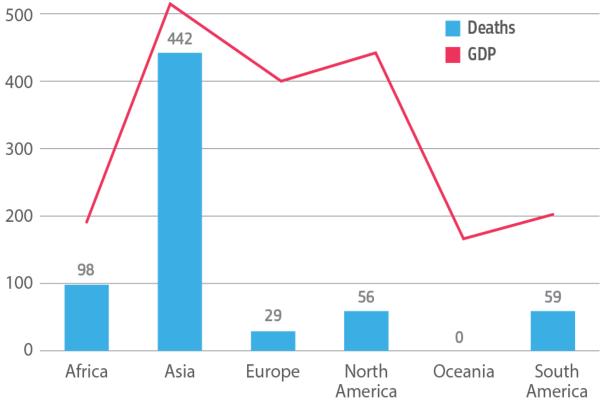

Overall, the number of chemical incidents in OECD countries is high compared to non-OECD countries. The severity of these accidents in terms of fatalities is much lower, however. This is an indication that actions taken to control the risks of chemical accidents have been successful in reducing deaths and injuries.

Recently, for example, the Commission has fostered the exchange and analysis of new and emerging risks in the rapidly changing oil and gas industry. Publications on the topic include the EU Good Practice Report on managing risks at liquefied natural gas and liquefied petroleum gas sites, and associated ‘lessons learned’ bulletins.

The European Commission continues to examine whether there are significant gaps in the existing regulatory framework for industrial accidents, particularly in relation to new and emerging risks arising from specific activities or dangerous substances.

Various EU funding instruments support research being carried out on the risks associated with industrial accidents. The Horizon Europe research programme for 2021–2027 supports research and technological development, intended to increase industrial capacities and mitigate risk, while one of the thematic priorities of the LIFE sub-programme for ‘Environment and Resource Efficiency’ supports the implementation of the Seveso III Directive. Furthermore, the Digital Europe programme is set to boost investments in cybersecurity, high-performance computing and data, artificial intelligence, and advanced digital skills.

The Joint Research Centre (JRC) has developed a number of tools to support national authorities in assessing the risk of industrial accidents. RAPID-N is an online risk assessment tool operating since 2012, which allows for a quick analysis and mapping of the risk of natech accidents at both local and regional levels. Accident Damage Analysis Module (ADAM) is a software application for assessing the physical effects of an industrial accident resulting from an unintended release of a dangerous substance.